The First Project Attempt

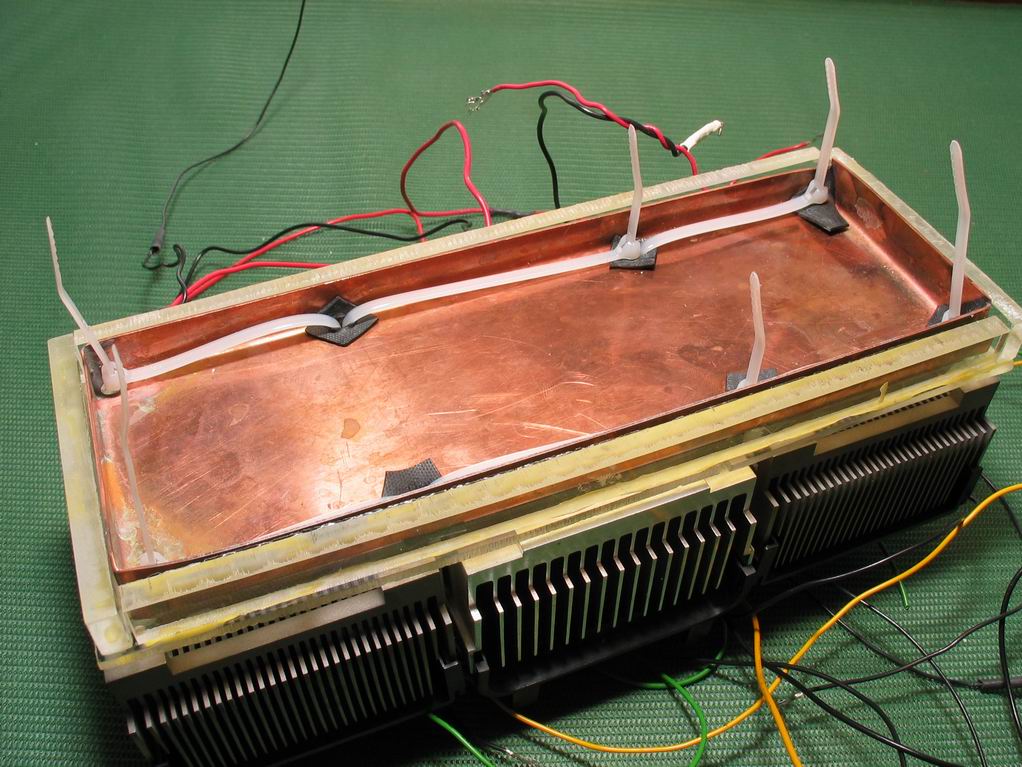

The original idea for this project was to test friction coefficients of different ski waxes at various temperatures. A copper trough was made to hold water which was going to be turned into ice. The temperature of this ice can be controlled using Peltier coolers. Peltier coolers use current to create temperature differences between two surfaces. This is why the trough was copper, as this is a good cheap conductor. The ice could be cooled to a desired temperature while the excess heat was dumped into a heat sink. Then separate ski waxes which are used for specific temperatures would be used and there friction coefficients measured using the same method as in the final project. In this case the graphs produced would have been used in a very quantitative way, instead of a qualitative one.

What went wrong:

After struggling for about a month, it was finally determined that the Peltier coolers were not going to work. They were supposed to work at 2A and 30V each, but they only reached 12V at 2A. This means we were not even getting half of the desired power (P = VI). The coolest the water got was +9 degrees Celsius. Three different types of heat sinks were used in order to try and maximize a temperature difference, but this did not work.

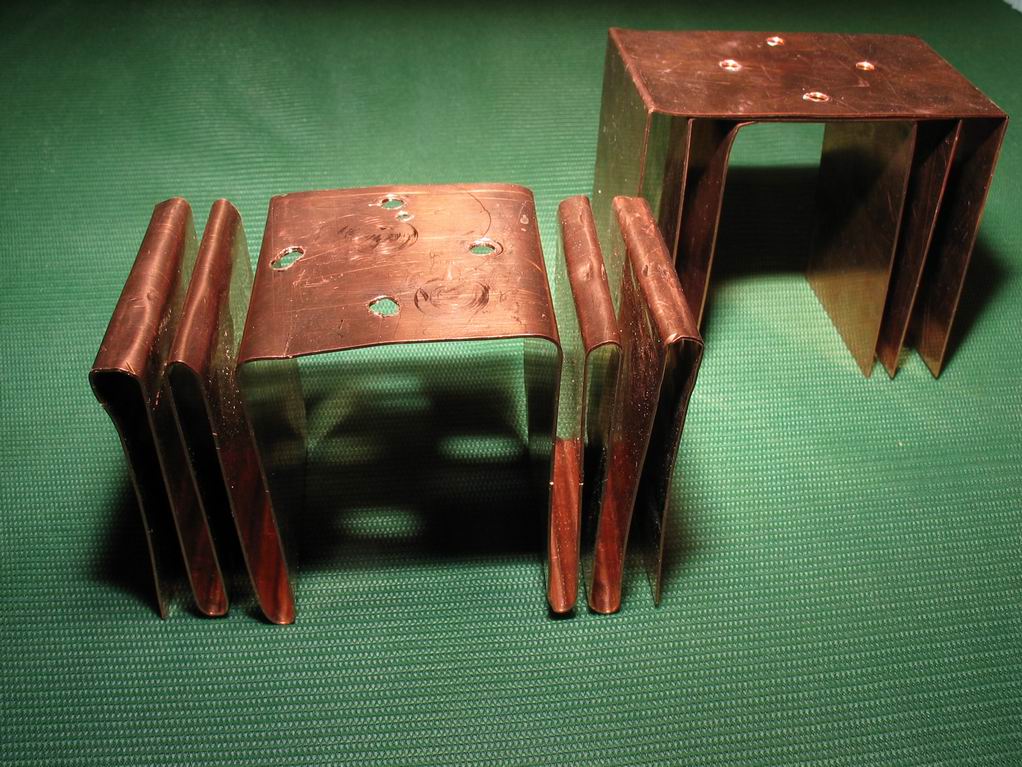

The Attempted Heat Sinks

The Final Product For this Attempt