Construction

The construction of the demonstration

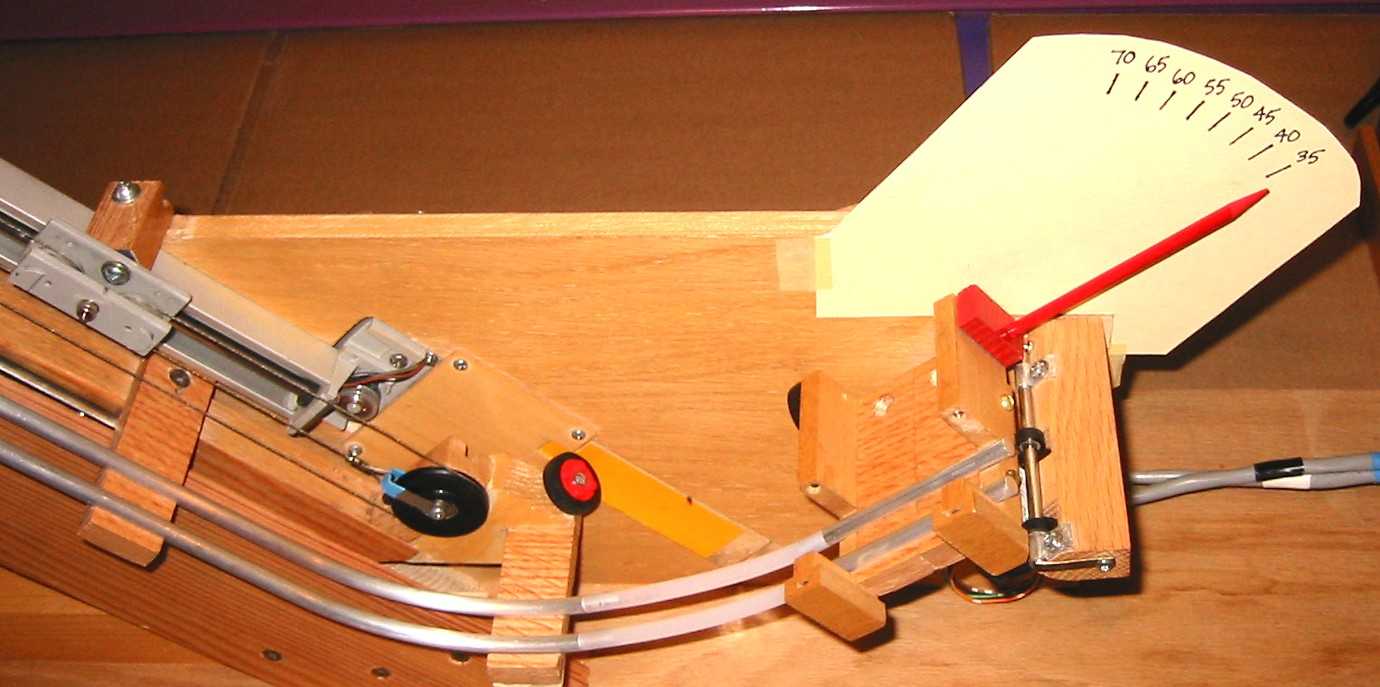

equipment involves constructing a launch ramp that

allowed for launches at various angles and velocities, modifying a surplus HP

7044A X-Y plotter to act as the ball catcher and

building a digital to analog (D/A) interface between

the computer parallel port and the X/Y inputs on the plotter. The other major

effort is in writing the software to control the demonstration equipment and

display the data for each launch. The Visual Basic code for this is included on

this site and should provide all the functionality needed to demonstrate the

concepts of projectile motion. Also the code is commented to a level that should

make it easy to modify for variations in the demonstration equipment design.

Once you have looked over the construction

details and have a good understanding of how the original project was built the

discussion below will give an appreciation of the relative success of various

parts of the design and might help with possible improvements.

What Worked Well

The components of the project that worked

quite well were :

- Speed gate, consisting of a pair of LED sources and

Photo-Darlington detectors allows accurate speed measurement.

- Parallel port interface, provides a good I/O circuit with

sufficient capacity for the D/A control logic and data input bits.

- Catcher, response time is good and range of motion is adequate.

- Ramp drive, using the plotter Y axis drive and the pulley system

to move the ramp is mechanically effective and gets the "Oh

cool!" response from the class.

- Software, using Visual Basic to manage the demo equipment was a

good trade-off of simplicity and flexibility.

What Might Be Done Differently

The weak point of the current design is definitely the

area around the adjustable ramp angle. The geometry of this setup only allows a

limited range of launch angles and results in poor stability of the rolling

ball on the lower (curved) portion of the ramp. Because the geometry of the

angle adjustment mechanism (see photo) using the flexible tubing between the

aluminum rail sections is not perfect, warps in the tubing occasionally result

in the ball hitting the speed sensor or bumping off the track entirely. Using a

slightly smaller wooden, plastic or glass ball that will sit slightly lower

between the rails, might increase stability. Alternately, if starting from

scratch, consider using a difference launch mechanism such as a spring or

compressed air.

The weak point of the current design is definitely the

area around the adjustable ramp angle. The geometry of this setup only allows a

limited range of launch angles and results in poor stability of the rolling

ball on the lower (curved) portion of the ramp. Because the geometry of the

angle adjustment mechanism (see photo) using the flexible tubing between the

aluminum rail sections is not perfect, warps in the tubing occasionally result

in the ball hitting the speed sensor or bumping off the track entirely. Using a

slightly smaller wooden, plastic or glass ball that will sit slightly lower

between the rails, might increase stability. Alternately, if starting from

scratch, consider using a difference launch mechanism such as a spring or

compressed air.