Home Design Concepts

Demonstration Other

Materials and Build of the Demonstration

Materials:

·

A bike and

its rear wheel (front wheel is optional)

·

A way to

stabilize the bike while the rear wheel is spinning

o Two chairs and a piece of wood did the trick as seen

in the photos below

·

A sheet of

aluminum to be cut

·

Nuts and

bolts

·

Electromagnet

·

Power

supply

·

Speed

sensor for the wheel in order to analyze the time it takes for it to slow in

detail

o Here a Garmin speed sensor was used along with a

Garmin head unit to record the speed

o A speed sensor and corresponding head unit can be

foregone if you are not looking to quantify the braking effect

Design:

The bulk of

the design is in retrofitting a rear bicycle wheel in order to be used as an

eddy current brake. The approach taken here was to cut a sheet of aluminum into

four separate pieces (shaped as quarter arcs of a circle) using a water jet

cutter such that when these four pieces are put together they will form a

circle with an inner radius equal to that of the radius of the rear bicycle

wheel being used (from the center of the wheel out to the lower profile of the

rim). The goal here is that this circle created with the aluminum fits snuggly

around the wheel in the location where an inner tube would normally sit on a

bicycle wheel. The outer radius of this aluminum circle will depend on the

dimensions of the bicycle being used. This means that the outer radius needs to

be large enough so that it sticks out from the rim and can pass through the

field produced by the electromagnet, but small enough so that it does not

interfere with the frame of the bicycle. Moreover, the thickness of the sheet

can be altered depending on the gap of the electromagnet that it has to pass

through. In this case the thickness of the sheet used was 1cm, but a greater

thickness if possible is better for creating a greater braking force. To

connect these four pieces together, slots were cut into each piece near each of

its ends and then nuts, bolts and small aluminum pieces (with holes also cut

into them) were used to fasten adjacent pieces together.

Once this

rear wheel has been created, it is inserted into the bicycle just as a rear

wheel usually would be. Next the bicycle must be positioned such that the rear

wheel is off the ground and will be able to spin so that the aluminum passes

through the gap of the electromagnet. Finally, the wheel can be spun by turning

the crank of the bicycle and then once it is up to the desired speed, the power

supplying the electromagnet can be switched on so that the magnetic field is

setup. The time taken for the wheel to come to a stop from a particular speed

when the magnetic field is present should be noticeably shorter than when the

magnetic field is switched off. When the magnetic field is not present, the

wheel would spin forever if it were not for frictional forces in the hub of the

wheel and air resistance. If the two stopping times with and without a magnetic

field are not noticeably different, this is because the magnetic field is not

strong enough and so it should be replaced with a stronger electromagnet until

the affect is observed.

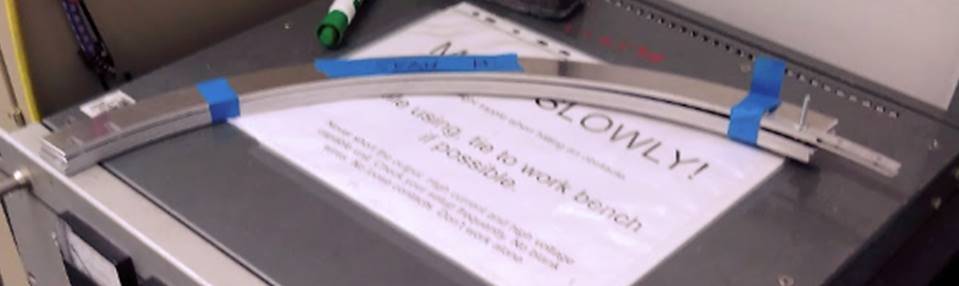

Pictures:

The images

below will hopefully provide a better visualization of the design and materials

used.